Sinda Turbo Quality Control

TURBO TECHNICS VSR400

Why choose Sinda ?

1. Think aftermarket turbo, Think Sinda!

- K418 shaft & wheel, heat-resistance>950℃

- Turbine housing with Silicon and molybdenum, high temperature & wear resistance

- Balancing testing for turbo core

- Nice detail processing & finishing

- Inspection during production and final inspection before shipment

2. How can we guarantee the quality?

A. Our factory strictly follows to the standard working process for Raw Material Supervision from turbo shaft,compressor housing, turbine housing to sealing kits to ensure each part with high quality standard before turbo installation&assembly.

B. Necessary testing & inspection during and after production

- Balancing testing for turbo core by TURBO TECHNICS VSR400 balancing machine

- Turbo charger vibration sorting

- Double check of the impeller before shipment to avoid rubbing problem

- Final inspection/a third-party inspection before shipment

C. Each turbo will be stamped with a “OK”or “PASS” on the compressor housing to show the turbo pass through the quality inspection.

What we are sure is that we can delivery qualify goods CONTINUOUSLY.

“Quality”, “Honesty” and “Service” are our top principles for business running.

How important is reliability to you? It is a Priority for us. Test, test and test some more.

1) CROMA Coordinate measuring machine

Coordinate measuring machine is mechanical systems designed to move a measuring probe to determine coordinates of points on a workpiece surface. They provide precise measurements of turbo parts for design, testing, assessment, profiling, and reverse engineering.

2) SEREIN Video Measuring Machine

Video measuring instrument is a compact, portable system for manual turbocharger parts inspection, measurement and documentation of small turbocharger components.

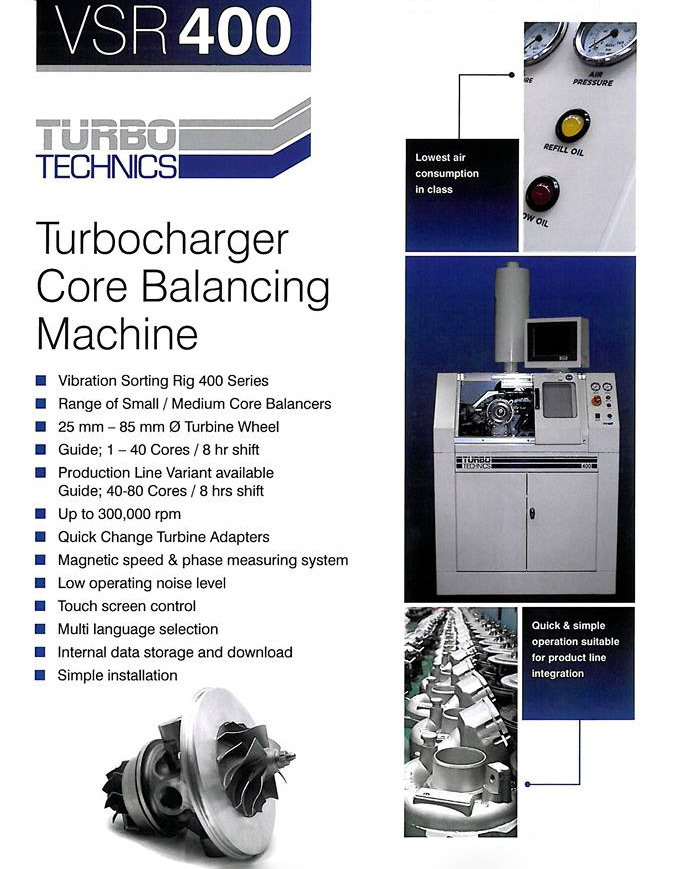

3)VSR 400 Turbocharger Core-Balancing Machine

The Turbo Technics VSR 400 has been designed with the medium-to-large sized workshop in mind and has the capacity to balance up to 100 Core Assemblies (CHRAs) during a typical 8 hour shift. comprehensive 5-stage filtration to remove the swarf generated during each balancing cut. Each of our turbo core /CHRA must be tested by the balancing machine to ensure the reliability and performance to avoid any potential problem.